Composite

Manufacturers are moving toward light-weight composite materials for their next generation of aircraft. Sonaca is at the forefront of this technology. Our production-process facilities include press, high-temperature autoclaves and out-of-autoclave composite manufacturing as RTM & SQRTM. Our workshops are set up with automated inspection equipment, lay-up (ATL, AFP) and milling.

Parts are manufactured using a variety of materials including epoxies, BMI, polycyanates, polyimides and thermoplastics.

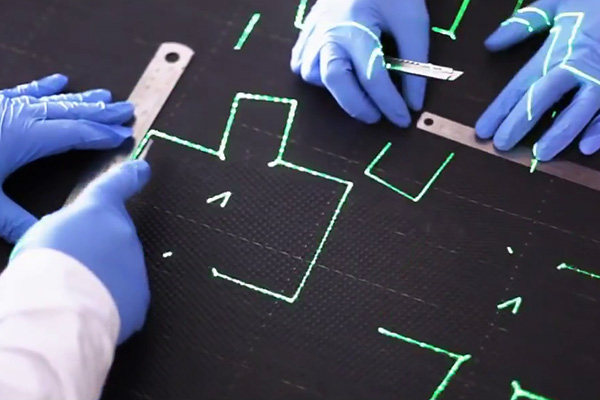

Hand-lay-up Composite

Composite manufacturing of hand-lay-up, autoclave cured aircraft parts and structures. Our facilities are close to our clients and low-cost location guarantees a competitive price.

Product identification

Composite parts and assemblies w/ sandwich panels and/or monolithic CFRP / GFRP

Location

Manufacturing sites & capabilities

Romania

Belgium

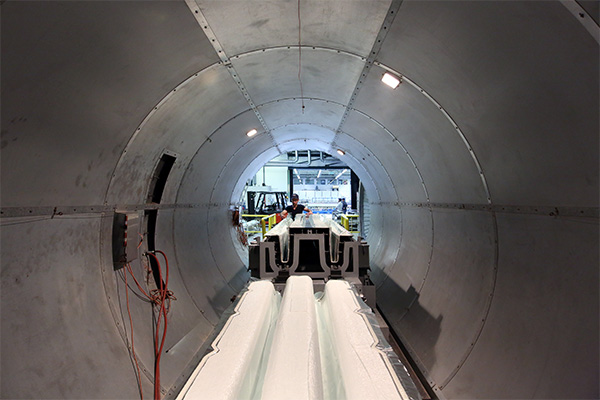

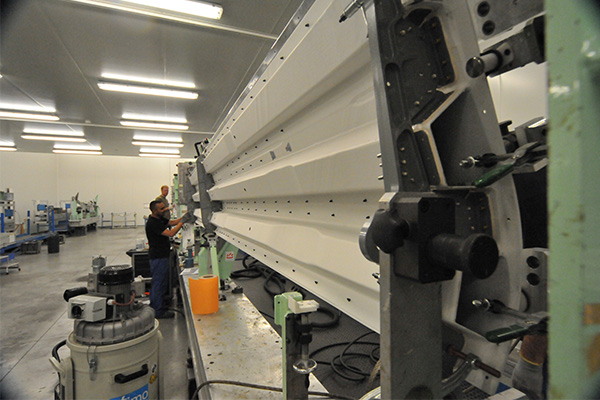

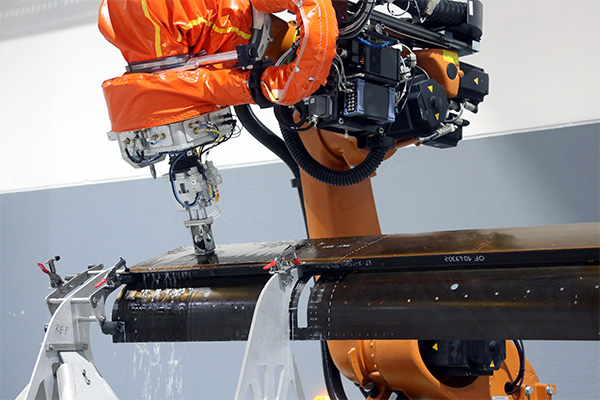

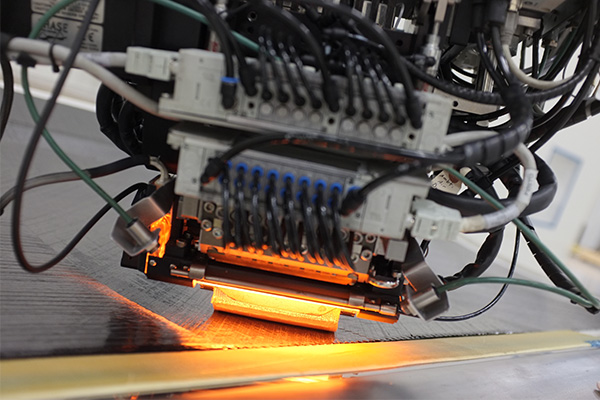

Advanced Composite

Sonaca develops advanced composite technologies as RTM & SQRTM to manufacture highly integrated structures and parts. This happens in a highly automated workshop that allows us to offer a robust and competitive solution.

Product identification

- Slats

- Flaps

- Pylon Trailing Edges

- Spatial structures

Location

Manufacturing sites & capabilities

Metal Bonding

For the aerospace industry’s needs, Sonaca has developed metal to metal bonding activities, including honeycomb core technology. Our capabilities include metal-to-metal bonding, metal-to-carbon bonding and surface pre-treatment prior to metal bonding.

Product identification

- Trailing edges

- De-icing inner skins

- Bird shields

- Spatial structures

Location