Machining

Sonaca offers a wide variety of aluminum and hard metal machining services. Our machining facilities are equipped with advanced technologies like high-speed machining pallet systems, robotics, and lean manufacturing methods. This enables us to machine parts up to 18 meters in length and create complex stringers using shot peening and milling techniques.

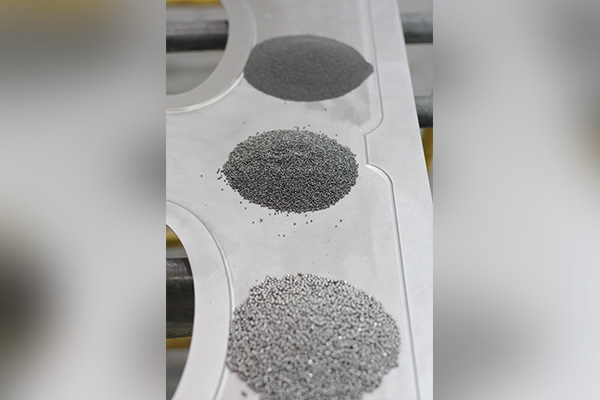

Aluminum small and medium machining parts

New equipment across our sites operates at higher speeds, allowing us to make parts and more complex products faster.

Product identification

- Aluminum machined metal parts

- Small assemblies

- Ribs, Fittings

- Access Panel

- Bracket

Location

Manufacturing sites & capabilities

Aluminum long bed machining & peen forming

Sonaca Montreal is fully integrated manufacturing facility with high-speed milling machines and one of the world’s largest computer-controlled shot peen machines. Our automated fastening machines and automated surface treatment line – the largest in Canada – are capable of processing aluminum aerostructures of 18 meters long by 3 meters wide.

Product identification

- Wing & Empennage skins

- Spars

Location

Manufacturing sites & capabilities

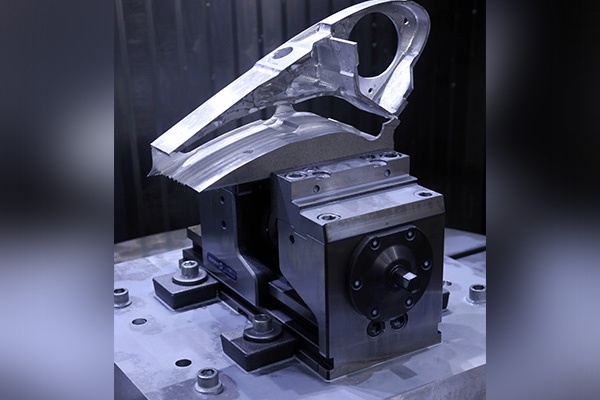

Hard metal machining

This 5-axis configuration allows you to drastically reduce the amount of setups on even the most difficult parts. Sonaca invests in new and emerging technologies to enhance performance, improve efficiencies and reduce costs.

Product identification

- Engine Fittings

- Wing attach fittings

- Pylon Chords

- Bulkheads

Location