Forming

Sonaca has the right advanced equipment and technical competence. Depending on application, we provide a variety of techniques such as stretch forming, roll forming and press forming.

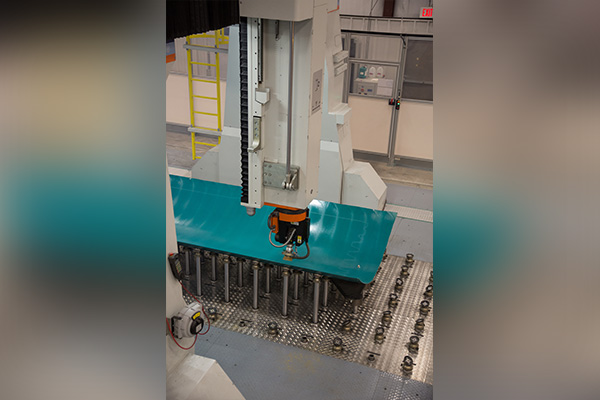

Large sheet metal forming

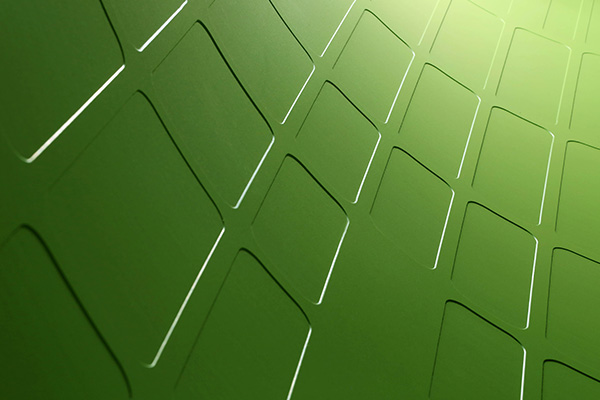

Sonaca can stretch complex parts like fuselage skins and leading edges. A wide range of processing needs is provided: Chemical machining, surface treatment, finishing and polishing. Those processes are kept in-house to create a more efficient supply chain, reduce inventory, transportation & handling costs and increase speed to market.

Product identification

- Large aluminum sheet metal parts

- Skin leading edges

- Panels

- Front & rear fuselage skins

- Winglet skins

- Doublers

Location

Manufacturing sites & capabilities

Small sheet metal forming

Sonaca delivers a broad range of fabrication capabilities, ranging from a single-piece component to complex, multiple-quantity orders. Our capabilities include everything from tooling to engineering. We bend, stretch, draw and stamp a myriad of materials such as aluminum alloys and other metals. Some facilities are located in low-cost countries to provide an internationally competitive price.

Product identification

- Ribs

- Frames

- Brackets

- Clips

- Small aluminum sheet metal parts

- Profile extrusion parts

- Winglet

- Weather seal. Painting services for machined parts

- La qualité et la performance de la production occidentale dans une installation " à guichet unique " aux meilleurs prix de revient du pays