Scientific instruments

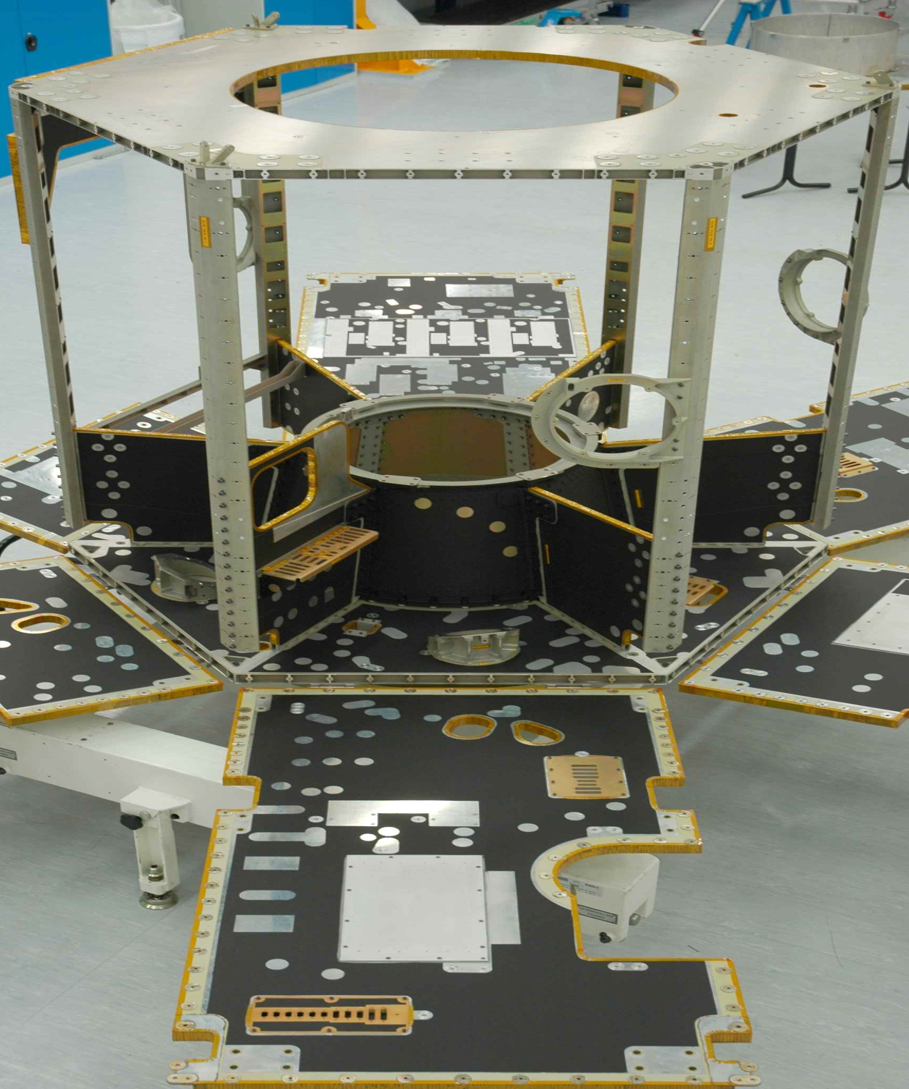

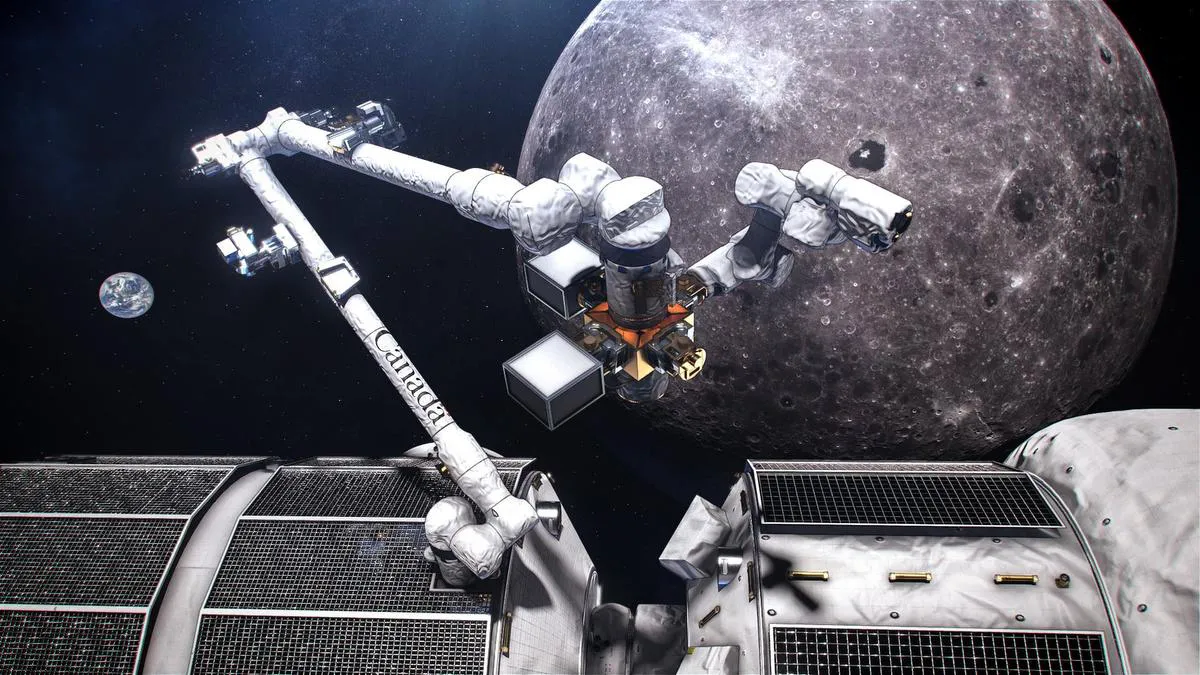

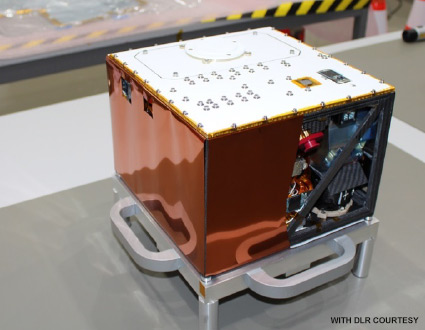

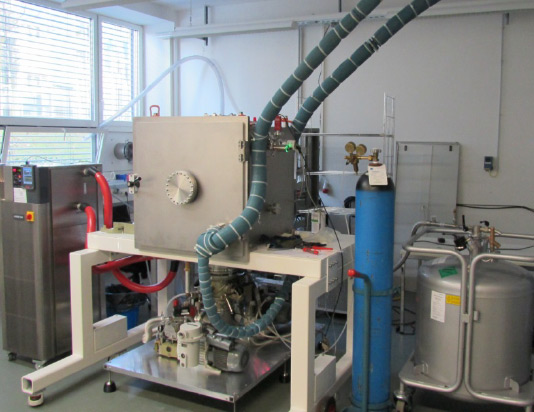

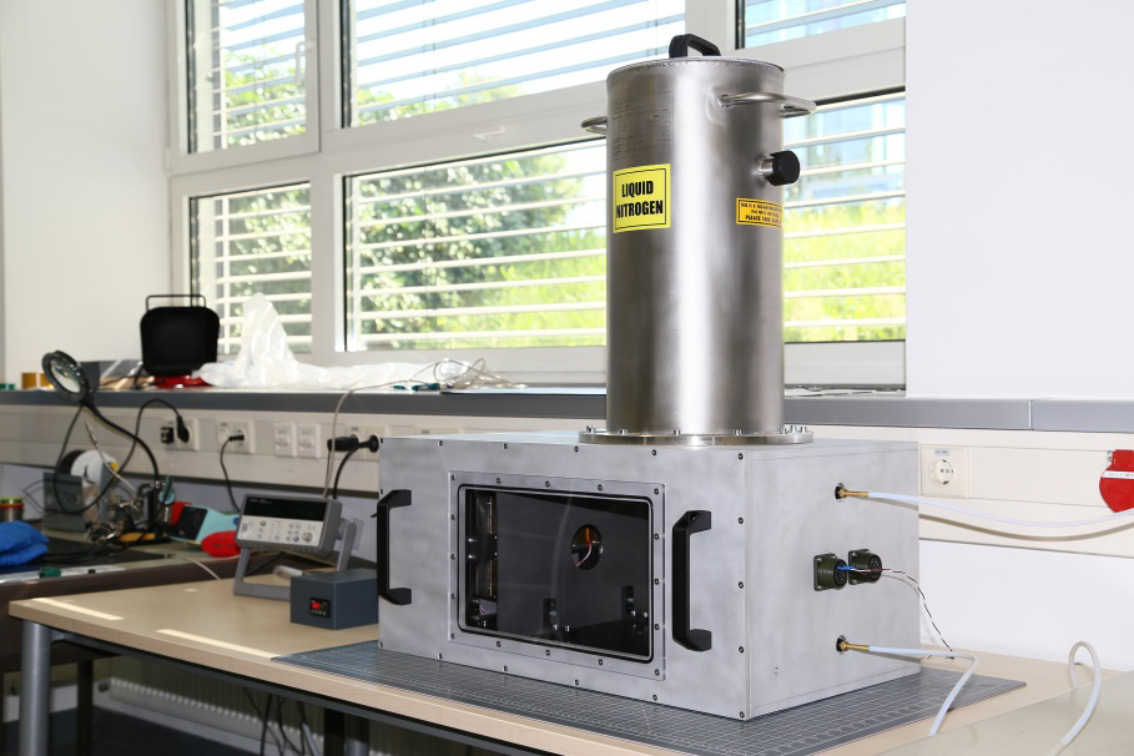

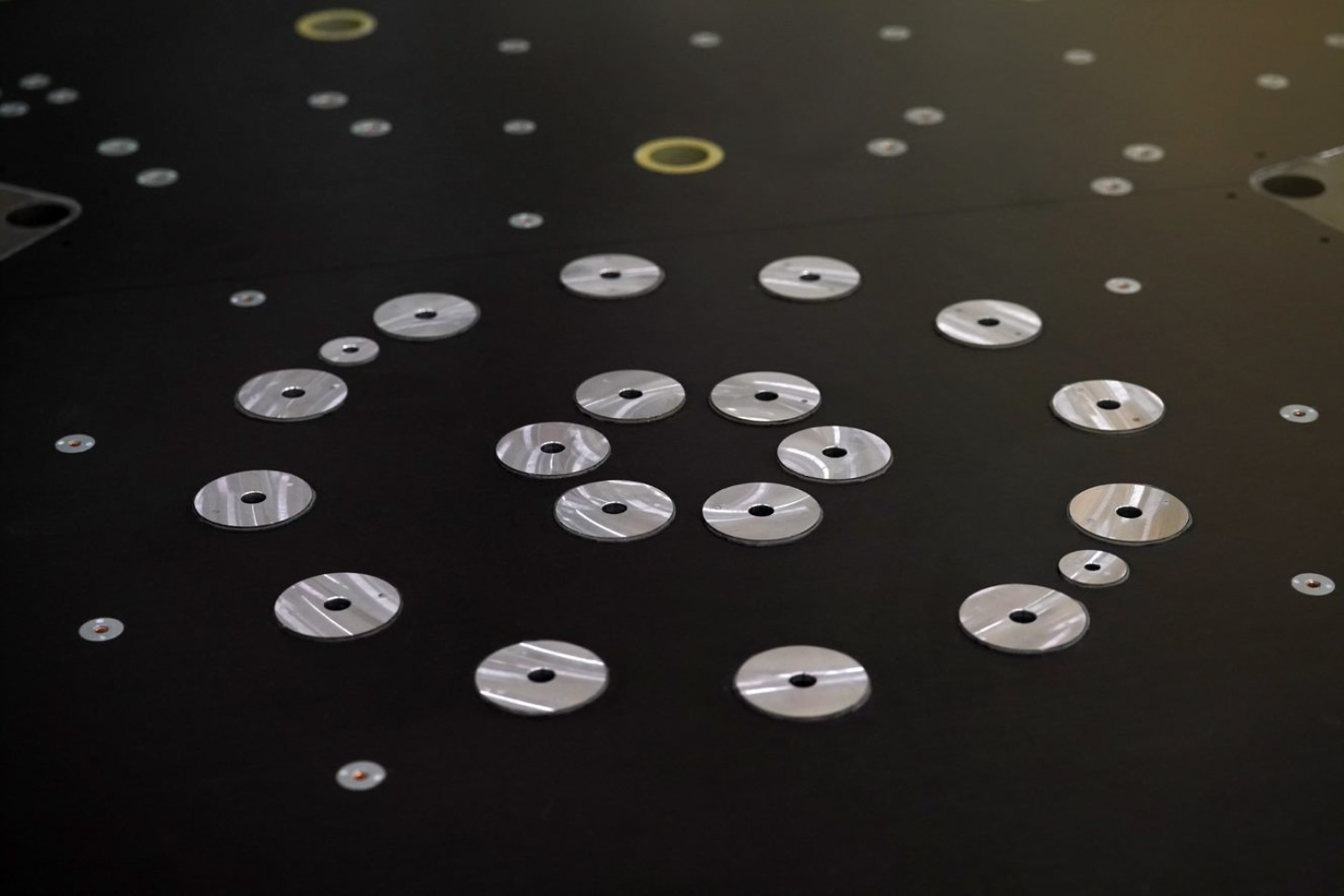

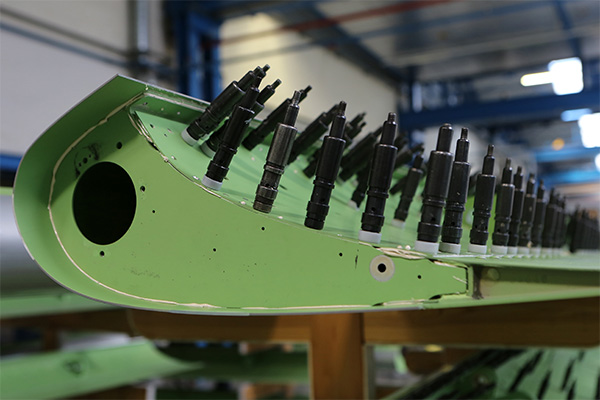

Industrial support to scientific institutions for the development, industrialization, production and qualification of scientific instruments in different domains: in situ planetary exploration (Mars, Moon, asteroids…), Earth observation or Solar system exploration.

- Project management support

- Technical coordination

- Systems engineering

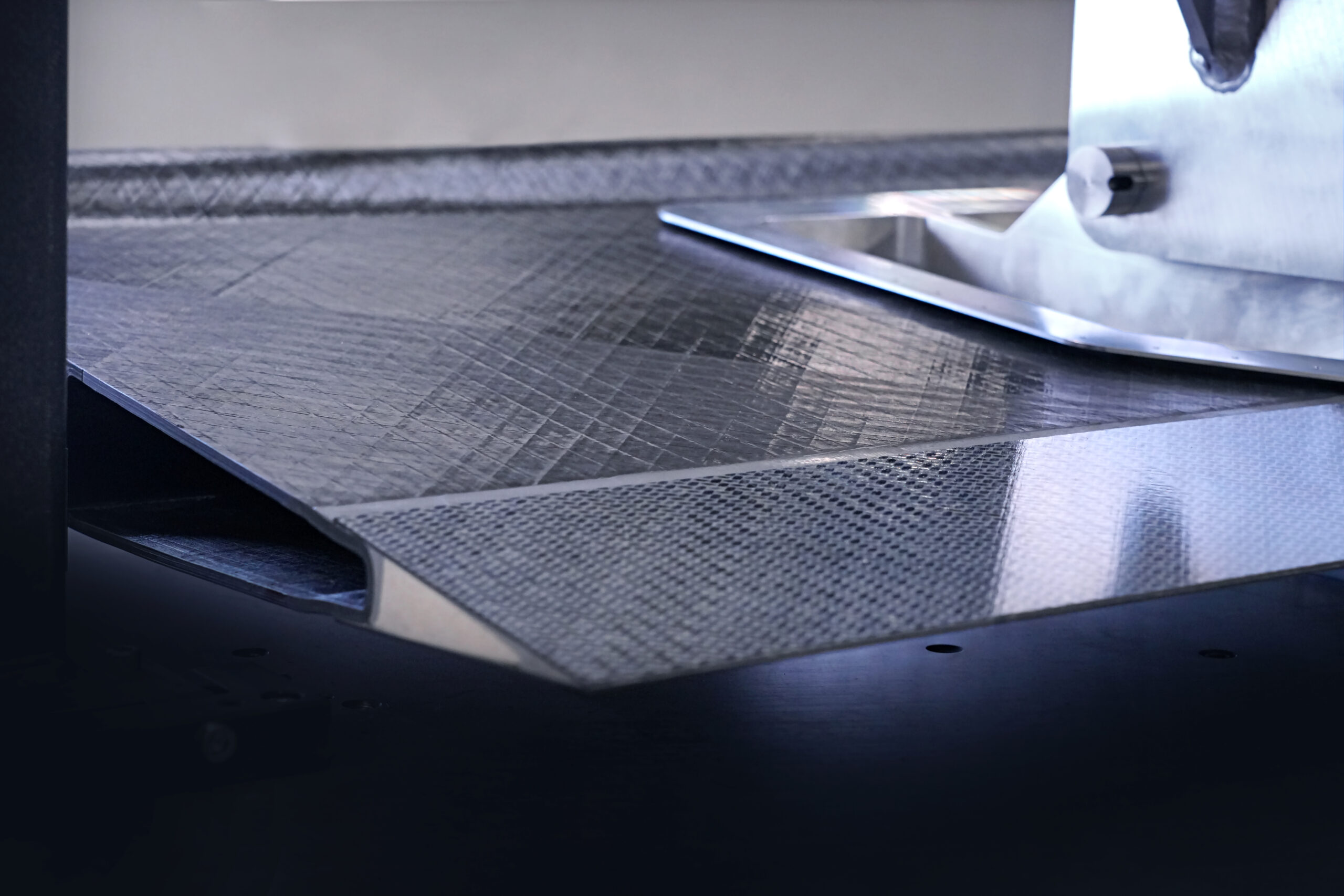

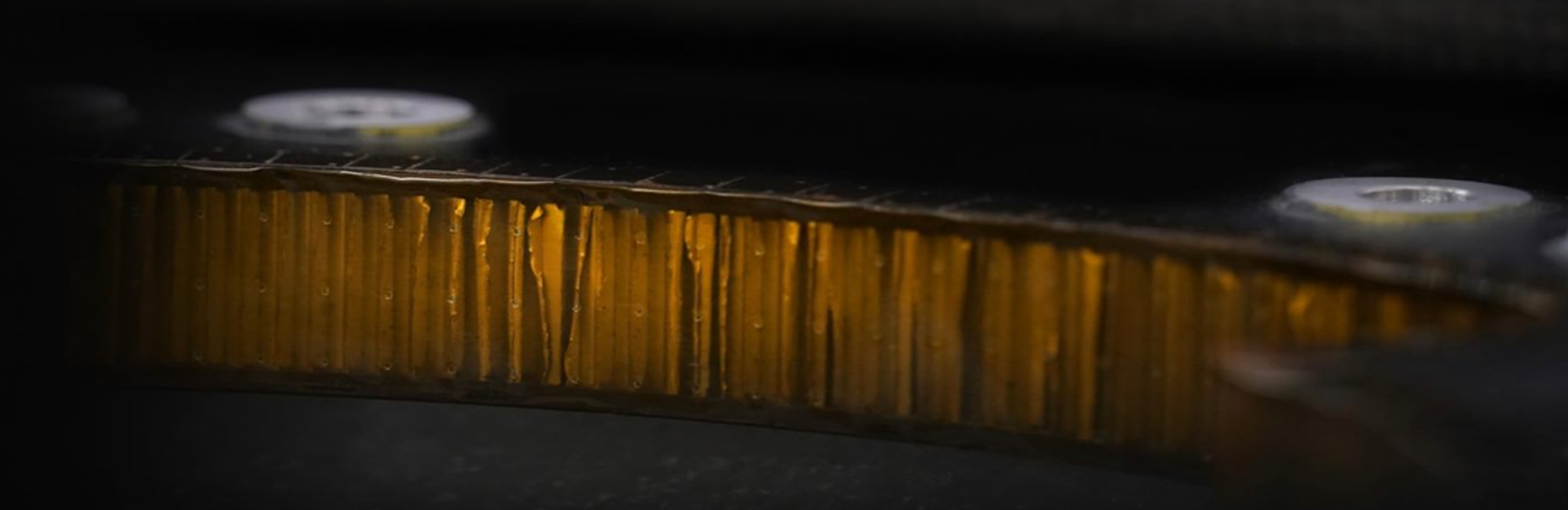

- AIT (Assembly Integration and Testing)

- Mechanical and thermal engineering

- Product and Quality Assurance

- Configuration management on the instrument and its subsystems